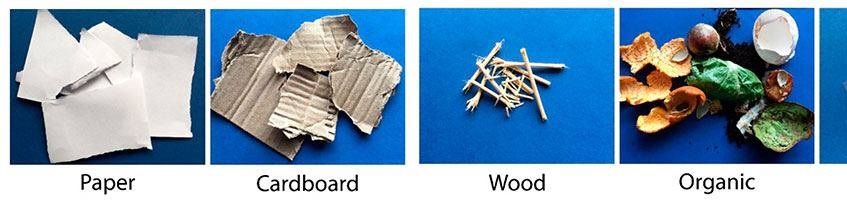

Refuse-Derived Fuel (RDF) pellets, crafted from municipal organic waste, agricultural biomass, paper/cardboard, and natural textile waste, provide industrial plants with a cost-effective, high-energy alternative to fossil fuels. These non-plastic feedstocks transform into engineered fuel, helping manufacturers cut energy costs, meet emission targets, and reduce landfill use—with properties tailored to specific industrial needs.

RDF Materials for Green Fuel Making

Discover how choosing the right raw materials optimizes RDF pellet performance. Explore feedstock-specific strategies to maximize energy output and operational efficiency—connect with our experts to design your tailored solution today.

- Turning Municipal Solid Waste into RDF for Industrial Use

- Optimizing RDF Production from Commercial Waste: Waste-to-Fuel Engineering Solutions

- RDF Waste Material for Energy Recovery: Optimizing Industrial Waste Recycling Systems

- RDF Waste Material: Sustainable Biomass Energy Solutions for Industrial Boilers

- Converting Textile Waste into RDF Fuel

- Waste Paper in RDF Production: High-Efficiency Material Preparation Guide

- Wood Waste in RDF Fuel Lines: Machinery, Feedstock Quality and Processing Methods

- Eco-Friendly Organic Waste to RDF Conversion

- Cardboard Recycling for RDF: Practical Plant Layout and Processing Insights

Industrial Value and Energy Potential of RDF Alternative Fuel

Refuse-Derived Fuel (RDF) waste material offers an energy-efficient and environmentally strategic solution for industrial sectors aiming to reduce fossil fuel consumption. By converting combustible components from municipal, commercial, and biomass waste into solid fuel, RDF supports a more circular energy economy across cement plants, paper mills, and power stations.

RDF Performance Across Industrial Boilers

Industrial users report that RDF fuel can achieve combustion efficiencies between 78% and 92%, depending on boiler compatibility and fuel quality. Cement kilns, which operate at high temperatures (up to 1,450°C), are particularly suited for RDF, which provides calorific values ranging from 15 to 25 MJ/kg.

The following table compares RDF performance across common industrial applications:

| Industry Sector | RDF Energy Output (MJ/kg) | RDF Usage Rate (Tons/Day) | Fuel Replacement Ratio (%) |

|---|---|---|---|

| Cement Plants | 20–24 | 120–250 | 40–60% |

| Paper Mills | 16–20 | 80–150 | 30–45% |

| Biomass Power Plants | 18–23 | 200–300 | 35–50% |

Key Drivers of RDF Adoption

- Cost Reduction: RDF can reduce fuel costs by up to 40% compared to coal or diesel in cement production.

- Carbon Emissions: RDF combustion emits 20–35% less CO₂ per unit of energy than traditional fossil fuels.

- Energy Security: For regions with limited fossil resources, RDF ensures a reliable, local energy source.

- Waste Reduction: Diverts over 60% of non-recyclable waste from landfills into industrial energy loops.

For factories pursuing carbon neutrality and alternative energy portfolios, **rdf waste material** serves as a practical step toward decarbonization. Unlike biomass or biogas systems, RDF can be integrated with minimal retrofitting into existing boiler infrastructure, making it both cost-effective and scalable.

Considerations for System Design

Energy Recovery Integration

Integrating RDF into energy systems requires precise fuel handling: moisture must be reduced to below 20%, and pellet sizes optimized (typically 40–70 mm in diameter) for combustion stability.

Emission Compliance and Quality Control

Factories in the EU and North America must meet strict NOx and dioxin emission limits. This necessitates real-time combustion monitoring via MES (Manufacturing Execution Systems) and pre-screening of feedstock using NIR (Near-Infrared Reflectance) analyzers.

-

Calorific Uniformity: Maintain a target deviation of ±1.5 MJ/kg.

-

Chlorine Content: RDF should not exceed 1.2% chlorine by weight to comply with EU standards.

-

Waste Stream Flexibility: Supports various inputs from municipal solid waste (MSW) to packaging rejects.

-

Operational Stability: Compatible with grate-fired and rotary kiln systems.

-

Fuel Blending Options: RDF can be co-fired with lignite or petcoke to adjust combustion characteristics.

Engineers designing RDF-capable energy systems must balance fuel consistency, storage logistics, and emissions control to achieve regulatory and operational efficiency.

Unlock long-term cost and energy savings with RDF – Connect with our specialists to get your industrial energy transition plan.

Impact of Waste Types on RDF Feedstock Quality

RDF fuel performance depends heavily on the quality and composition of the waste feedstock used. Different waste streams—municipal solid waste (MSW), commercial waste, and industrial residues—offer varied calorific values and moisture profiles.

Key Calorific Profiles by Waste Type

- MSW Plastics: 30–38 MJ/kg

- Cardboard and Paper Waste: 12–17 MJ/kg

- Organic Fractions (Food, Green Waste): 6–10 MJ/kg

- Textile Waste: 14–18 MJ/kg

Mixed MSW often contains over 25% organic material, which lowers overall RDF quality. Therefore, high-energy components such as plastics, packaging films, and non-recyclable paper are targeted in RDF preprocessing.

Segmenting waste streams by source enables better fuel quality control. For instance, separating high-chlorine PVC plastics before processing can reduce harmful emissions and extend boiler life.

Proper feedstock preparation ensures RDF meets both energy performance and environmental compliance targets.

Get expert guidance on optimizing RDF feedstock selection—reach out to our engineering consultants today.

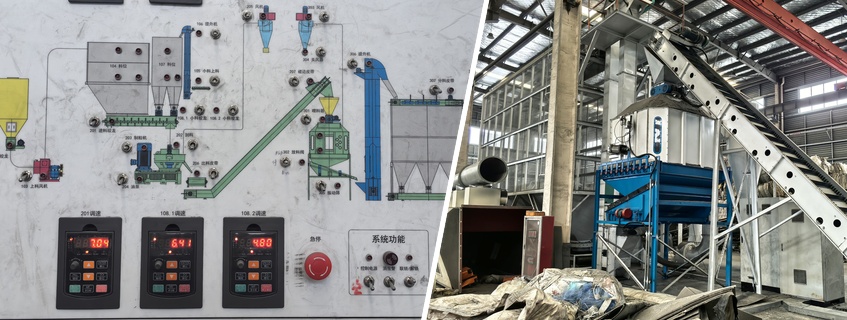

Overview of RDF Pre-Treatment and Pelletizing Technologies

Complete RDF Pre-processing and Pelletizing Line

Efficient RDF production requires a carefully structured processing line that includes shredding, drying, sorting, and densifying stages. The goal is to produce stable, high-energy fuel with uniform particle size and moisture content.

Typical Equipment and Functions

- Primary Shredders: Reduce waste to <250mm; capacity ~15 tons/hour

- Drying Systems: Lower moisture to <20%; energy input ~150 kWh/ton

- Magnetic Separators: Extract ferrous materials

- Refiners and Pelletizers: Achieve 50–80mm fuel size with bulk density of 650–750 kg/m³

Industrial Deployment Guidelines

Facilities producing over 200 tons/day of RDF typically adopt continuous flow systems with MES integration. Pelletizers equipped with automatic blade adjustment and temperature monitoring improve pellet consistency and reduce downtime.

Choosing scalable machinery and integrating real-time control improves both output and safety in RDF fuel production.

Designing Customized RDF Feedstock Strategies for Specific Industries

Different industries require tailored RDF formulations to balance performance, emissions, and economic returns. Cement kilns, for example, can tolerate higher ash content than paper mills or biomass boilers.

Key Parameters by Industry

- Cement Plants: Accept RDF with 15–25% ash, high calorific plastic content

- Paper Mills: Require low ash (<10%) and chlorine (<0.7%) RDF to protect boilers

- Power Stations: Prefer homogenous pellet fuels with stable combustion curves

Raw material handling systems must allow multiple input types, with automated feeders and blending hoppers to enable fuel flexibility.

Get Your Customized RDF Fuel Strategy Blueprint – Contact Our Technical Team Now.