Can waste-to-energy projects generate clean energy without compromising on environmental standards? RDF (Refuse-Derived Fuel) pellet technology delivers on this promise, enabling efficient combustion that minimizes CO2, NOx, and particulate emissions.

RDF Pellet Technology: Emission Reduction & Energy

This article explores how RDF pellet production works, its role in optimizing energy conversion, and how it enhances both sustainability and operational efficiency—offering insights for waste-to-energy projects aiming to meet strict emission regulations.

What Is RDF and Waste-to-Energy Technology?

Refuse-Derived Fuel (RDF) is a type of fuel produced from non-recyclable waste materials. It is commonly used in waste-to-energy (WtE) plants to generate electricity and heat. RDF is made by processing municipal solid waste (MSW) or industrial waste, separating out recyclable materials and turning the rest into a fuel that can be used in energy generation.

RDF is an essential component of the waste-to-energy technology that helps reduce the environmental impact of waste while providing an alternative energy source. As landfills become overcrowded and the environmental effects of waste disposal become more evident, RDF and WtE technologies are seen as effective solutions to manage waste and produce clean energy.

By using RDF in energy generation, industries can not only reduce their dependency on fossil fuels but also lower greenhouse gas emissions and contribute to a more sustainable energy ecosystem. Waste-to-energy plants that employ RDF can operate more efficiently, turning what would have been waste into valuable energy.

-

RDF in Waste Management: RDF technology plays a key role in managing non-recyclable waste by converting it into a usable form of energy.

-

Energy Generation: WtE plants utilizing RDF contribute significantly to energy security by producing renewable electricity and heat.

-

Sustainability: RDF technology supports a circular economy by turning waste into energy, reducing the environmental impact of waste disposal.

Waste-to-energy solutions like RDF are critical for industries striving for sustainability and efficient waste management.

How RDF Pellet Technology Works and Its Role in Waste-to-Energy Conversion

Hot Sale RDF Pellet Prodcution Line & Machines

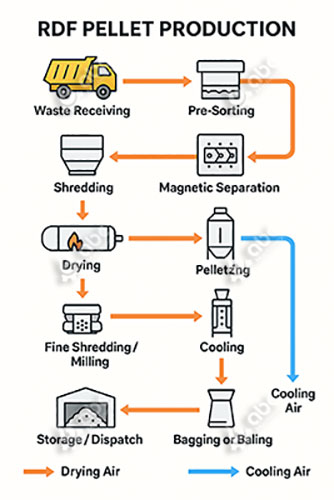

RDF pellet technology involves compressing refuse-derived fuel into small, dense pellets that are easy to handle, transport, and burn efficiently. The process starts with sorting waste, followed by shredding and drying. The material is then pelletized, forming compact pellets that can be fed into energy generation systems.

The main advantage of RDF pellet technology is its ability to achieve higher combustion efficiency compared to bulk RDF. The uniform size and density of the pellets allow for better control over the combustion process, resulting in more efficient and cleaner energy production.

The pellets are designed to burn more efficiently than traditional waste, with minimal emissions. This technology helps ensure that energy generation from waste is not only effective but also environmentally friendly. RDF pellet technology also enables better energy optimization, which reduces operational costs and enhances the overall energy output of the plant.

-

Efficient Combustion: RDF pellets burn cleaner and more efficiently than bulk waste materials, reducing the risk of high emissions.

-

Pellet Production: The production of RDF pellets involves grinding and compressing waste into a uniform, dense form for optimal combustion.

-

Cost-Effective Energy Production: By improving combustion efficiency, RDF pellet technology lowers the cost of energy production in waste-to-energy plants.

Investing in RDF pellet technology can improve operational efficiency and reduce long-term energy costs, making it a sustainable solution for waste-to-energy projects.

How RDF Pellet Technology Reduces Emissions and Improves Energy Efficiency

RDF pellet technology plays a crucial role in emission reduction in waste-to-energy projects. One of the primary benefits is the reduction of harmful emissions such as CO2, NOx, and particulate matter. This is achieved through the efficient combustion of RDF pellets, which ensures that less energy is wasted during the burning process.

By using RDF pellets, waste-to-energy plants can maintain a cleaner and more controlled combustion process. The higher energy density of the pellets means that less material is required to produce the same amount of energy, leading to lower emissions per unit of energy generated.

In addition to reducing emissions, RDF pellet technology also enhances the overall energy efficiency of the plant. With better control over combustion, the plant can operate at optimal levels, reducing fuel consumption and improving energy output.

-

Emission Reduction: RDF pellet technology helps reduce CO2 emissions by ensuring more efficient combustion.

-

Energy Efficiency: RDF pellets lead to better heat generation, reducing energy losses during combustion.

-

Sustainability: The use of RDF pellets in WtE plants helps meet international environmental standards for emission reduction.

How RDF Pellets Reduce Emissions in WtE Projects

Contact us to explore how RDF pellet technology can enhance your waste-to-energy project and improve emission control.

The Future of RDF Pellet Technology in Global Industrial Applications

The adoption of RDF pellet technology in industrial applications is growing globally. Countries and industries looking to reduce their environmental footprint and enhance energy production are increasingly investing in RDF and waste-to-energy solutions.

RDF pellet technology is not limited to waste-to-energy plants. It has also found applications in industries such as cement production, where it is used as a supplementary fuel to reduce the reliance on fossil fuels. The versatility of RDF pellets makes them an attractive option for various industrial sectors looking to improve sustainability.

A key factor in the future growth of RDF pellet technology is its ability to offer an attractive return on investment (ROI). By reducing waste disposal costs, lowering energy costs, and ensuring compliance with environmental regulations, RDF pellet technology offers significant financial benefits for investors and industries.

-

Global Adoption: RDF pellet technology is expanding in regions around the world, including Europe, North America, and Asia.

-

Industry Applications: Beyond waste-to-energy, RDF pellets are used in industries like cement production and manufacturing.

-

Investment Feasibility: Investors in RDF pellet technology can see substantial returns due to reduced operational costs and improved energy efficiency.

Explore the potential of RDF pellet technology in your industry—connect with our experts to discuss investment opportunities and project feasibility.