Discover which countries lead the RDF fuel market by capacity and output—and where the biggest business and technology opportunities lie in waste-to-energy today.

Top RDF Pellet Producing Countries and Their Waste to Energy Potential

Looking to start an RDF project or optimize your plant's cost efficiency? Contact ABC Machinery, a trusted manufacturer and supplier, to get tailored insights and free quotes for your business needs.

Global Overview of RDF Fuel Producing Countries

The RDF market is a crucial component of the global waste-to-energy industry, playing a vital role in converting waste materials into renewable energy sources. As countries around the world focus on improving their waste management systems and reducing carbon footprints, RDF fuel production has seen a significant rise in various regions. Top RDF fuel producing countries like Germany, Japan, and the United States have become global leaders in RDF fuel production, setting high standards for both output and efficiency.

Key factors contributing to the success of these regions include:

- Advanced waste sorting and processing technologies

- Strong government incentives and support for waste-to-energy initiatives

- An established infrastructure for RDF collection, transportation, and utilization

| Country | Annual RDF Output (tons) | Typical Equipment Used | Primary Application |

|---|---|---|---|

| Germany | 4,200,000 | 2-stage shredder, baler, dryer | Co-firing in cement plants |

| Japan | 2,900,000 | Press granulator, infrared sorting | Industrial boilers |

| USA | 5,300,000 | Magnetic separator, pellet mill | Biomass power plants |

| UK | 3,100,000 | RDF line with PLC automation | Export and local WtE |

The RDF fuel production landscape continues to evolve with new innovations, creating opportunities for global investors to enter the market and enhance their energy efficiency.

Interested in tapping into the growing RDF market and exploring investment opportunities for your waste-to-energy project? Connect with ABC Machinery to discuss plant solutions, get detailed cost breakdowns, and partner with a reliable supplier for long-term business success.

Industrial Landscape and Investment Opportunities in Key RDF Producing Countries

The industrial RDF fuel landscape in countries like Germany, Sweden, and the U.S. offers numerous investment opportunities for those involved in waste-to-energy projects. Germany leads the way with a robust RDF fuel industry, backed by stringent environmental policies and government support. Sweden’s impressive network of waste-to-energy plants also contributes significantly to its status as a top producer of RDF fuel. The country’s RDF fuel investment opportunities continue to grow as it seeks to expand its waste-to-energy infrastructure.

In addition to these top producers, countries like the UK and France also offer promising opportunities for investments in waste-to-energy plants, especially with their expanding recycling programs and increasing demand for renewable energy solutions. Key investment areas include:

- Modernizing RDF fuel production facilities to improve output

- Integrating innovative waste sorting and fuel processing technologies

- Expanding infrastructure for the collection and transportation of RDF feedstock

RDF Fuel Production Processes and Technological Innovations

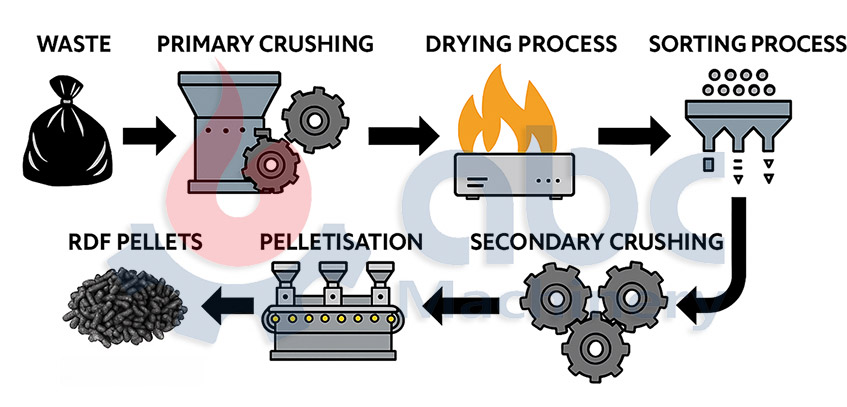

Refuse Derived Fuel Production Process

Technological innovation in RDF fuel production technology is at the heart of increasing global waste to energy technology capacities. Countries at the forefront of RDF fuel production have been integrating cutting-edge technologies to optimize production efficiency and reduce costs. Notable innovations include the use of advanced sorting techniques, such as near-infrared reflectance (NIR) technology, to separate valuable materials from waste streams. This allows for higher quality RDF fuel with greater energy efficiency.

In addition, modern RDF fuel production processes now incorporate automated systems that enhance production speed and reduce labor costs. The use of MES (Manufacturing Execution Systems) has also been instrumental in tracking and optimizing production workflows, ensuring that plants operate at maximum efficiency. These advancements are critical for scaling up RDF production and achieving cost-effective waste-to-energy solutions.

So, want to enhance your RDF production process with advanced technology and efficient equipment? ABC Machinery, a leading manufacturer, is here to help—contact us for project consultations, cost analyses, and to explore how we can support your business in this evolving market.

Future Trends and Global Collaboration in the RDF Fuel Market

The future RDF fuel market trends point toward increased collaboration between countries and companies in the global waste-to-energy collaborations sector. As nations work together to tackle the global waste crisis, international partnerships will be key in driving the development of new technologies and expanding RDF fuel production.

In the coming years, the RDF fuel industry will likely see an increase in cross-border investments, particularly in emerging markets where waste-to-energy technologies are just beginning to gain traction. The collaboration between developed and developing nations will open doors for knowledge sharing, resource pooling, and more efficient waste management systems.

For investors and industry professionals looking to enter the RDF fuel market, exploring international partnerships and collaboration opportunities can provide a competitive edge in an evolving industry. Whether you need project advice, cost estimates, or equipment details, contact our team today to take the first step toward successful RDF business ventures.