Maximize RDF Profits: Turn Waste into High-Value Energy Pellets

Raw Material Sourcing for RDF Pellet Production & Recycling

Optimize RDF Feedstock: Sourcing & Pre-Treatment for High-Calorific Pellets

Effective raw material sourcing is the first step in optimizing the RDF (Refuse-Derived Fuel) process, which is central to producing high-quality biofuel pellets. The key to sourcing the right materials lies in understanding the composition of RDF and ensuring a steady supply from reliable suppliers. RDF typically consists of waste from municipal solid waste (MSW), such as textile waste, wood waste,paper, and certain organic residues—that must meet strict quality specs to maximize energy output.

| Feedstock | Typical Sources | Pre-treatment | NCV (dry, MJ kg-1) | Critical QC Points |

|---|---|---|---|---|

| Waste Paper | sorted office paper | De-staple, screen to < 30 mm | 14–16 | Ink residue < 3 %, PVC tape < 1 % |

| Wood Waste | Demolition timber, sawdust | De-nail, shred to < 50 mm | 17–19 | In-feed moisture ≤ 25 % |

| Organic Waste | Food scraps, garden trim | De-water, 3–5 d windrow | 10–13 | Cl- < 0.8 %, particle size < 20 mm |

| Textile Waste | Used clothing, automotive fabric, leather off-cuts | Cut to < 30 mm, metal detector | 20–22 | Total Cl- < 0.7 %, heavy-metal pass |

When sourcing raw materials for RDF production, you must assess several factors including material quality, cost, and environmental compliance. Working with certified RDF raw material suppliers ensures that these requirements are met, while also maintaining a sustainable supply chain. Moreover, it’s essential to evaluate the cost-effectiveness of sourcing strategies, balancing the transportation costs with the quality of the material being supplied.

5 Key considerations in sourcing RDF raw materials:

- 1.Material quality: Ensuring that the raw materials meet industry standards for energy content and purity. (Net Calorific Value (NCV) ≥ 18 MJ/kg, moisture < 15 %, chlorine < 0.7 %.)

- 2.Cost efficiency: Negotiating favorable terms with suppliers to maintain a competitive cost structure for your rdf factory.

- 3.Supplier reliability: Working with long-term, dependable suppliers to reduce material shortages.

- 4.Sustainability: Prioritizing eco-friendly materials that align with global environmental standards.

- 5.Logistics Integration: Establish preprocessing hubs within 150 km of the pellet plant to reduce CO₂ emissions.

RDF Recycling Process & Technology Implementation

RDF Recycling Process & Key Technology Implementation

The RDF recycling process is key to turning waste into valuable fuel for energy production. The process begins by segregating waste streams, followed by sorting, cleaning, and processing into standardized RDF. Technologies such as Mechanical Biological Treatment (MBT), optical sorting, and trommel screening are essential for maximizing efficiency.

Key technologies in RDF recycling:

- Mechanical Biological Treatment (MBT): A process that uses mechanical means to shred and separate organic materials before biological treatment to stabilize the waste.

- Optical Sorting: Advanced systems that utilize near-infrared reflectance (NIR) to separate plastic and metal contaminants from the organic fraction of the waste.

- Trommel Screens: Rotary screens used for separating fine and coarse materials during the RDF recycling process.

Advanced technologies not only streamline the recycling process but also contribute to higher recovery rates and cleaner RDF. This, in turn, boosts the calorific value of the resulting fuel pellets, ensuring that they meet the energy requirements of power plants and other users.

RDF recycling efficiency can be further enhanced by implementing continuous monitoring systems such as Manufacturing Execution Systems (MES). These systems allow manufacturers to track the entire recycling process, making real-time adjustments to improve performance.

For more information on RDF recycling technologies, contact our technical team for a customized solution.

RDF Production Equipment and Line Design

RDF Pellet Production Equipment & Line Layout Design

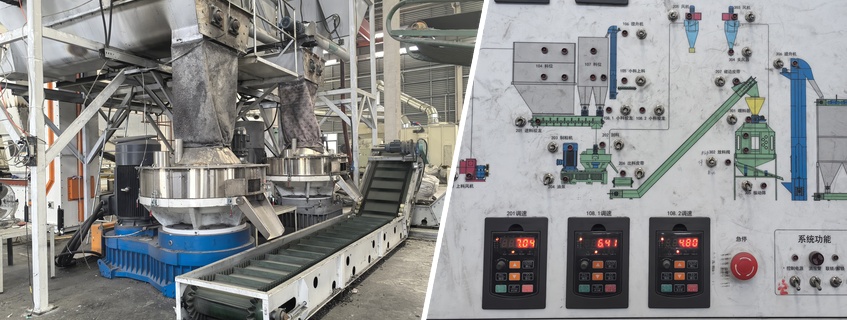

Selecting the right equipment and designing the appropriate production line is vital for optimizing RDF pellet production. The machinery used in RDF production directly influences the efficiency and quality of the pellets produced. This includes shredders, compactors, dryers, and pellet mills, each of which must be carefully chosen to suit the materials being processed.

Equipment and production line design considerations:

- Shredders and Crushers: Proper selection ensures that the raw materials are broken down into uniform sizes, which is essential for consistent pellet quality.

- Pellet Mills: Choosing pellet mills with high throughput capacity ensures the continuous production of high-quality pellets.

- Drying Systems: Effective drying systems ensure that RDF materials have the correct moisture content before pelletizing, which significantly impacts the energy efficiency of the process.

ABC Machinery designs and supplies complete biofuel pellets processing solutions, including shredders, crushers, dryers, and high-capacity Vertical Ring Die Pellet Mill. Our engineers focus on durability, efficiency, and adaptability to different feedstocks. Feel free to contact us anytime for RDF solutions and equipment pricing!

Best Practices for RDF Recycling Efficiency and Future Trends (2025-2030)

The RDF recycling industry is continuously evolving, and staying ahead of the curve is key for maintaining competitive advantage. Some of the best practices for improving RDF recycling efficiency include:

- Integration of Smart Technologies: Using data analytics and AI to optimize waste sorting and processing.

- Energy Recovery Systems: Implementing systems that capture excess heat during the RDF recycling process and redirect it to other parts of the plant.

- Sustainability Practices: Prioritizing the use of low-carbon technologies and recyclable materials to align with global sustainability goals.

Industry Outlook: RDF production companies that combine efficient raw material sourcing, modern RDF recycling technology, and well-designed pellet production lines will stay competitive in the global renewable energy market.