Complete biomass briqutete plant is composed by raw material processing (may include crushser/hammer mill, dryer, etc.), conveying, briquetting (biomass briquette machine), packaging, or even carbonizing (charcoal kiln or carbonization furnace if you want to make charcoal briquettes) processes.

Make Different Shapes of Biomass Briquette

ABC Machinery provides you with a more rational biomass briquette production process with fewer operators required. For the same productivity, we have lower power consumption and shorter time to get returns on investment. Moreover, our core accessories are more durable, stable and can produce more pellets. If you are planning to build your own biomass briquette plant and start a business, please click the button below to contact us!

What raw materials can the briquetting plant process?

| By Type | By Application | By Geography |

|---|---|---|

|

Agro waste Briquettes Wood Briquettes |

Power Generation Thermal Energy Others |

North America: U.S. Canada, Mexico Europe:UK, Germany, France, Italy Asia-Pacific:Japan,India, South Korea,Australia South America:Brazil, Saudi Arabia |

Machines Required for Biomass Briquetting Plant

Hammer mill/crusher (optional): used to pulverize coarse raw materials into required size, generally less than 3mm, so that the crushed material can meet briquetting requirements.

0.3~7TPH Hammer Mill / Crusher for Biomass Briquetting Machine

Dryer: many briquetting raw materials contain much more water than required (around 15%). Therefore, these raw materials shall be dried till the moisture content reaches the required amount.

Rotary Drum Dryer for Briquetting

Conveyor: used to convey the raw materials into the briquette press evenly.

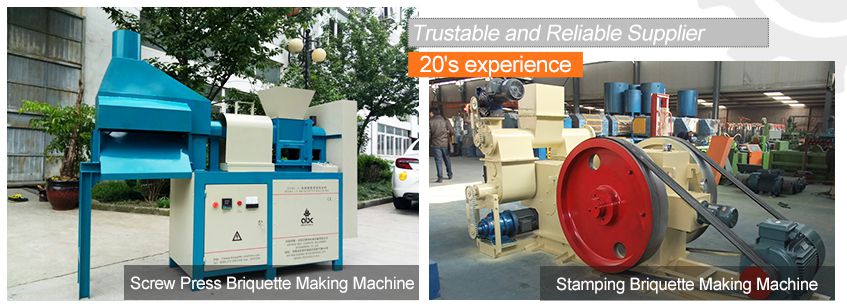

Biomass briquette machine: you can choose to use screw briquette press (making hollow wood briquettes or charcoal for sale), or punching briquetting machine (making round solid biomass briquettes or pellets for own use).

Biomass Briquette Making Machine for Sale

Charcoal kiln (carbonization furnace, optional): if you want to make charcoal briquettes, you need this carbonization furnace. Workers put the biomass briquettes orderly into the kiln (furnace), then seal the kiln, and ignite the waste briquettes to let the integrated biomass briquettes carbonize at high temperature (about 700 degrees Celsius). After 2-3days reaction, the charcoal briquettes are made.

Charcoal Kiln Carbonized Briquette

Carbonization waste gas collection device (optional): our biomass briquette plant can strictly complete with the Environmental Protection Rules in many countries.

Packaging machine (optional): the biomass briquettes or charcoal briquettes can be packed for sale or for storage.complete biomass briquette plant flowchart.

Featrues of Complete Biomass Briquette Plant

- Large output and many choices. The output of the rod making machine is large, and there are many types of equipment to choose from.Capacity: 200kg/H ~ 1T/H with screw briquetting machine; 500kg/H ~ 5T/H with punching biomass briquette press.

- No binder needed in the briquette production process. Each small set of briquette machine is an inseparable system, which guarantees the complete operation of the briquette machine factory with simple operation and first-class quality.

Video of Complete Biomass Briquette Plant

How to build a biomass briquette plant? – buy high quality biomass briquette machine for charcoal briquette making: HOT sale biomass briquette plant offered biomass briquette processing machine manufacturer or supplier, guide on process of biomass briquette production and how to start animal feed pellet making business with limited cost in The Czech Republic, Guatemala, South Korea, Japan, Thailand, Indonesia, etc.

Location of the biomass briquette production plant is very vital, and the best position should be near the supply of raw materials and also close to the consumers. One should also carry a good market analysis to ascertain the competition and what is driving the demands of the briquette. It is also vital to know and meet all the legal requirements and ensure the business is registered as required by the relevant authority. Do you want to know more information about our products? Do you want to receive more and better guidance on establishing a biomass briquette plant? Please contact us as soon as possible!

BEFORE YOU SEND INQUIRY

Please provide us with project information as much as possible:

- For a complete project: the material availability,the required output capacity,the process technology,your budgetary and financing status,the estimated starting time,etc.

- For singular machinery: the model,the capacity,your budgetary information,other requirements,etc.

- For spare parts: size and dimensions,material and weight,and your drawings with details,you can send the drawing to info@bioenergy-machine.com

Detailed information is greatly helpful for us to give you the best-customized offer/quotation at the soonest time.