-

Product Name: Flat Die Pellet Mill

-

Production Output: 50~800Kg/H

-

Raw Materials: It is applicable for making wood, sawdust, straw, rice husk, bark, weeds, alfalfa, etc. into high density biomass pellets.

-

Applications: The pellets are mainly used as fuel for home heating, central heating boiler, animal bedding, or as feed for poultry. Now, biomas pellets have become the replacement of coal, petroleum, natural gas, and other fossil fuels because they are energy-saving and can decrease carbon emission. Plastic pellets and fertilizer pellets can also be made by flat die pellet mill.

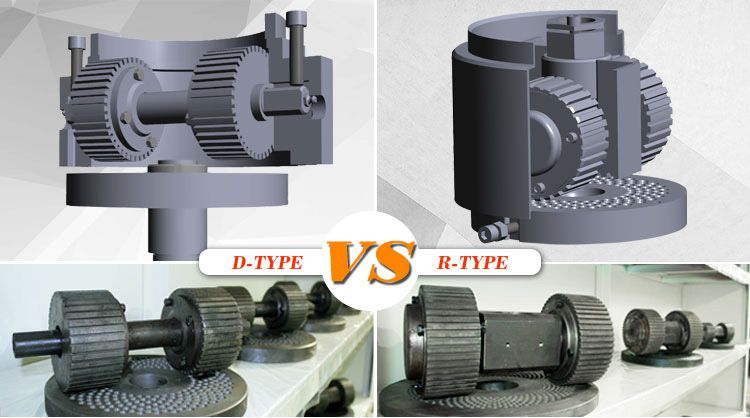

Small pellet mill classification

There are 2 types of flat die pellet mill: Die-turned pellet mill and Roller-turned pellet mill.- Die-turned pellet mill is often called D-type pellet mill, which means the pellet mill main part flat die rotates while the roller is stationary. This type of small pellet mill is usually applied to process softwood like pine, cypress, basswood, fir, bamboo, or most agricultural waste.

- Roller-turned pellet mill is abbreviated as R-type pellet mill, which means the pellet mill roller rotates while the flat die is stationary. Because of its higher pressure, this type of small pellet mill is often used to process hardwood raw materials, such as oak, birch, cypress, elm tree, larch, poplar, etc.

According to its power source, flat die pellet mill can be separated into the following series:

D-type:

B series: can process Eucalyptus wood, Pine, Birch, Poplar, Bamboo Shavings, etc. into biomass pellets. This series adopt half-covered electric motor design, which looks small and brief in appearance.

| Model Number | Power (kw) | Output (kg/h) | N.W./G.W. (kg) | Package Size (mm) |

|---|---|---|---|---|

| ZLSP150B | 3phase, 5.5 | 50-100 | 95/100 | 800*450*700 |

| ZLSP200B | 3phase, 7.5 | 80-120 | 200/230 | 1050*480*930 |

| ZLSP230B | 3phase, 11 | 120-200 | 290/320 | 1180*540*1000 |

| ZLSP260B | 3phase, 15 | 160-250 | 320/360 | 1240*540*950 |

| ZLSP300B | 3phase, 22 | 250-400 | 350/380 | 1300*560*1100 |

A series: can process Twigs, Straw, Leaves, Sawdust, etc. It adopts diesel engine, which is movable and convenient to use. Both D-type and R-type small pelle mills have diesel engine driven series.

| Model Number | Power (Hp) | Output (kg/h) | N.W./G.W. (kg) | Packing Size (mm) |

|---|---|---|---|---|

| ZLSP150A | 10 | 50-100 | 180/220 | 1000*500*750 |

| ZLSP200A | 15 | 80-120 | 210/240 | 1460*750*900 |

| ZLSP230A | 22 | 120-200 | 280/310 | 1560*850*1000 |

| ZLSP260A | 33 | 160-250 | 330/360 | 1200*500*1070 |

| ZLSP300A | 41 | 250-400 | 410/450 | 1220*600*1000 |

C series: can process Corn Stalk, Wheat Straw, Cotton Stalk, Branches, Leaves, Sawdust, and other agricultural waste. It adopts fully covered electric motor design, and the electric motor is CE approved.

| Model Number | Power (kw) | Output (kg/h) | N.W./G.W. (kg) | Package Size (mm) |

|---|---|---|---|---|

| ZLSP150C | 3phase, 5.5 | 60-110 | 105/125 | 1000*480*780 |

| ZLSP200C | 3phase, 7.5 | 80-120 | 210/230 | 1050*550*830 |

| ZLSP230C | 3phase, 11 | 120-200 | 290/320 | 1200*560*950 |

| ZLSP260C | 3phase, 15 | 160-250 | 340/370 | 1240*580*1000 |

| ZLSP300C | 3phase, 22 | 250-400 | 425/465 | 1300*620*1100 |

P series: can process stalk, peanut shell, weed, etc. Movable, easy to install and operate, this is the first choice for outdoor pellets production. ABC Machinery is also the first in China to manufacture PTO powered small pellet mill.

| Model | Power (Hp) | Output (kg/h) | Weight (kg) | Packing Size (mm) |

|---|---|---|---|---|

| ZLSP-D 150P | ≥8 | 50-100 | 90/110 | 900*540*1020 |

| ZLSP-D 200P | ≥15 | 80-20 | 130/150 | 1000*540*1020 |

| ZLSP-D 230P | ≥22 | 120-200 | 175/200 | 1000*540*1020 |

| ZLSP-D 260P | ≥30 | 160-250 | 235/255 | 1050*540*900 |

| ZLSP-D 300P | ≥55 | 250-400 | 305/325 | 1100*540*1000 |

R-type:

B series: can process oak, birch, cypress, elm tree, larch, poplar, etc.

| Model Number | Power (kw) | Output (kg/h) | N.W./G.W. (kg) | Package Size (mm) |

|---|---|---|---|---|

| ZLSP200B R-type | 3phase, 7.5 | 80-120 | 215/245 | 950*450*1050 |

| ZLSP300B R-type | 3phase, 22 | 250-350 | 540/575 | 1350*750*1400 |

| ZLSP400B R-type | 3phase, 30 | 350-450 | 770/810 | 1400*800*1450 |

| ZLSP550B R-type | 3phase, 55 | 500-800 | 1770 | 2300*750*1850 |

A series: uses diesel engine to make hardwood pellets.

| Model Number | Power (Hp) | Output (kg/h) | Weight (kg) | Package Size (mm) |

|---|---|---|---|---|

| ZLSP200A R-type | 15 | 80-120 | 320/350 | 1460x950x1100 |

| ZLSP300A R-type | 41 | 250-350 | 850/890 | 1100x700x2480 |

| ZLSP400A R-type | 55 | 350-450 | 1010/1050 | 1300x800x2600 |

Biomass Pellets Made by ABC Machinery Small Pellet Mill

Small pellet mill operation video

What are the advantages of our small pellet mill?

- Scientific and reasonable structure design, small area covering, low noise.

- Dry in, dry out. Easy to pelletize, high yield, low power consumption.

- High pellet forming rate; the pellets made by our flat die pellet mill has high hardness, smooth and even shiny surface, easy for storage and transportation.

- The pellet size has various choices: 4, 6, 8, 10, 12mm, or other customized diameter. At the same time, you can customize the flat die with different thickness and compression ratio to adapt to different materials and realize best pelleting result.

- The whole machine is casted. Flat die and main shaft are made from 40Cr which is wear-resistant. The service life of roller and die can reach 500hr.

- Easy to operate and maintain, safe to use (with Emergency Stop button), no special requirements for working site.

--------------------Agents Recruiting!-------------------

IF you have the ability to import, and there is big market potential for biomass pellet mills in your local area, it is great chance for you to be our AGENT!

Sincerely expect your joining!

If you want to have the PRICE LIST of Small Pellet Mill, Please don't hesitate to contact us NOW!