- Project Name: 8-10 TPH Chicken Feed Pellet Production Processing Plant

- Raw Materials: Corn, wheat, soybean meal, fish meal, etc.

- Purpose: Clients invest in large chicken feed pellet production business to open up the local market in the chicken feed business.

8-10 Ton/H Chicken Feed Manufacturing Plant for Sale

8-10 Ton/H Chicken Feed Pellet Processing Plant

ABC Machinery has successfully constructed an impressive 8-10TPH Chicken Feed Pellet Line for one of our esteemed clients. This state-of-the-art production line comprises various essential components, including a storage silo, crusher, mixer, pellet mill, pellet cooler, crumbler, rotary screener, feed pellet packaging machine, and more. Each element plays a crucial role in ensuring the efficient and high-quality production of chicken feed pellets. For further insights into the poultry feed pellet making technology, we encourage you to explore and familiarize yourself with the intricacies of this innovative process.

Pictures Display for the Industrial Chicken Feed Processing Plant

Main Equipment in the 8-10 Ton/H Chicken Feed Pellet Production Line

At the heart of the chicken feed pellet line, we have the electric control cabinet, which serves as the central control unit for the entire production system. This cabinet efficiently regulates and coordinates the operation of each component, ensuring a seamless and synchronized workflow.

Central Control Cabinet for 8-10tph Chicken Feed Project Pellet Production Project

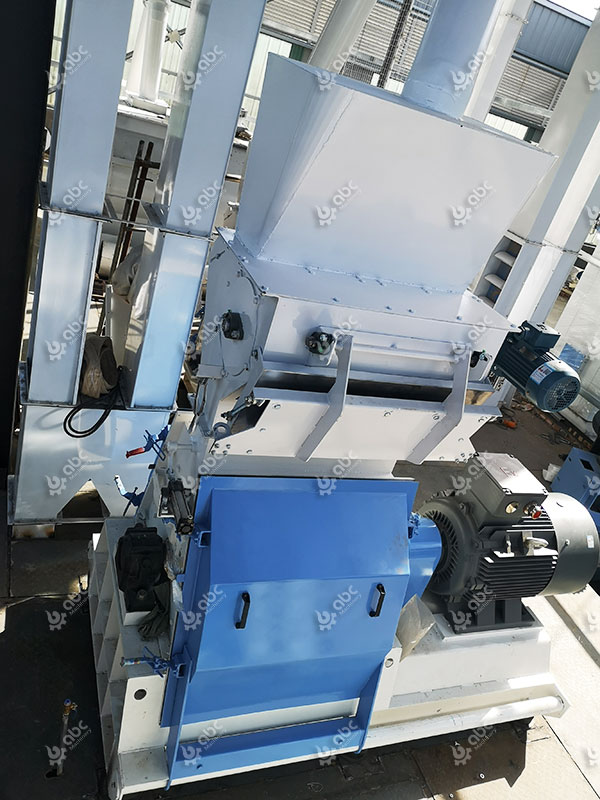

The hammer mill is an integral part of the chicken feed pellet line, responsible for grinding the raw materials into smaller particles. This process enhances the digestibility and nutrient absorption of the feed, ultimately promoting the health and growth of the chickens. The finely ground feed is then ready for the subsequent stages of the pelleting process.

Chicken Feed Production Hammer Mill

Our BPM45 Chicken Feed Pellet Mill is a key player in transforming the finely ground feed into compact and uniform pellets. Through the implementation of advanced technology, this pellet mill exerts the necessary pressure and heat to bind the feed particles together, resulting in durable and nutritionally balanced chicken feed pellets.

Following the pelletizing stage, the rotary screener efficiently separates the pellets from any oversized or undersized particles. This process ensures that only the correctly sized and shaped pellets proceed to the next phase of the production line. The rotary screener guarantees the consistent quality of the final chicken feed pellets.

Once the screening process is complete, the feed pellets are then ready for packaging. Our sophisticated packaging machines are capable of efficiently and accurately packaging the feed pellets into bags. This automated process not only enhances productivity but also ensures the hygiene and integrity of the final product. The packaged chicken feed pellets are now conveniently ready for distribution and consumption.

Main Equipment for 8-10 TPH Poultry Feed Pellet Line

ABC Machinery takes great pride in the successful implementation of this chicken feed pellet line, as it exemplifies our commitment to providing cutting-edge technology and comprehensive solutions to meet the diverse needs of our clients. The production line we have designed and built guarantees the production of high-quality and nutritious chicken feed pellets, supporting the optimal growth and health of poultry. We invite you to delve deeper into the poultry feed pellet making technology, where you can uncover more detailed information about the intricacies of this revolutionary process.

In conclusion, our 8-10TPH Chicken Feed Pellet Line is a testament to our expertise in the field of feed pellet production. With a range of meticulously designed components working in harmony, this production line ensures the efficient and reliable manufacturing of top-quality chicken feed pellets. By investing in our state-of-the-art equipment and advanced technology, you can elevate your poultry farming operations and achieve remarkable results. Explore the poultry feed pellet making technology further to discover the endless possibilities it offers for optimizing your chicken feed production.