It is known to all that biomass wood pellet fuel is a new type of combustion pellet that has garnered widespread attention as a renewable and clean energy source. Therefore, an increasing number of individuals are diving into establishing their own industrial wood pellet production plants. Whether on a small or large scale, biomass pellet processing plants prove to be a secure and profitable venture.

Buy Industial Wood Pellet Mill at Factory Price

For novice investors, you might be wondering, how much does a hot-selling pellet mill cost? Don't worry! Our article will provide you with a quotation and project plan for investing in a wood pellet plant. We will guide you through the key steps involved in wood pellet production, offering technical support for your current or future wood pellet plant to help you capitalize on the use of wood pellets and maximize your profits!

What is the Price of Continuously Working Wood Pellet Machinery?

Take 500 kg per hour production capacity as an example, how much does it cost a wood pellet plant that has a 500kg/h outputs? The cost to establish a fully-equipped 500kg/h wood pellet mill, typically ranges from 25,000 to 35,000 USD.

Cost-effective Wood Pellet Mill for Sale

Buy cheap wood pellets making machines from wood pellets equipment manufacturer or supplier at factory price, get FREE technical instruction of wood pellets production process and business plan to set up wood pellet projects at low cost! Please do not hesitate to contact us!

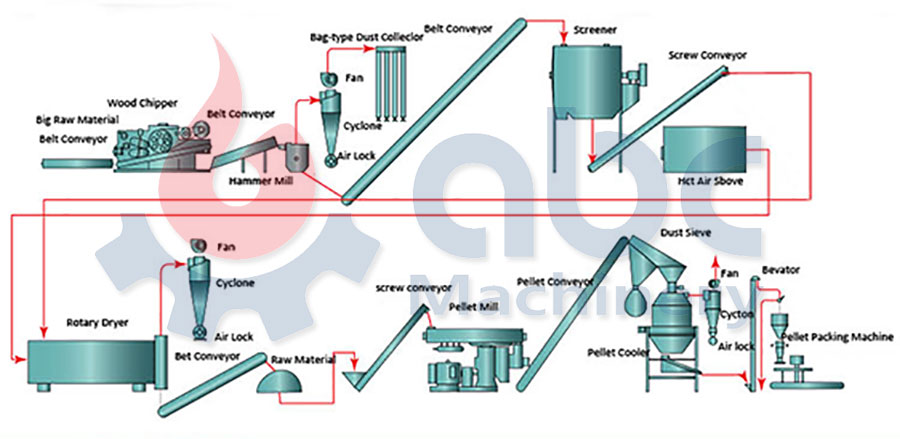

Complete Guide On Wood Pellets Production Process

Biomass Pellet Production Processing Flow Chart

-

Pretreatment of Raw Materials

Sieving: The raw material is transported to the sieve machine through the screw conveyor for sieving to remove the larger wood chips or nails and other debris.

Drying:Wood chip fuel pellets have stricter requirements on the moisture content of raw materials, which are screened and then transported through hot air to the drum dryer for drying.

Cyclone separation: In the process of drying and conveying raw materials, a large amount of moisture is produced, and the moisture is discharged through the cyclone separator.

Material conveying: The raw material conveying after pretreatment needs corresponding conveying equipment, according to the need, screw conveyor, strand conveyor and elevator can be used to convey the material to the corresponding equipment.

-

Pelletizing & Forming

The wood chip pellet mill is the key equipment of the production line, which can be applied to different raw materials such as sawdust, corn straw, bean straw, cotton straw, peanut shells and so on. The density of processed wood chips burning pellets can reach 1.0-1.3 tons per cubic meter.

-

Cooling

Discharging burning wood chips pellets with temperatures up to 80 ~ 90°C, the structure is more relaxed and easily broken, they must be cooled to room temperature by a counter flow cooling system before they can be bagged into storage or fed by belt conveyor into silos and elevators. The equipment is equipped with cooling fans and cyclone separators that return the separated powder to the previous process for re-pelletizing.

-

Vibrating Screen for Pellet Screening

After the pellet fuel is cooled and screened using a vibrating screen, screening is required to screen out the crushed material to ensure the quality of the wood chip burning pellets. After sieving out the crushed material, it is returned to the previous process for re-pelletizing.

Investment Analysis: What about the global market for biomass wood pellets

The combustion of wood pellet fuel is the combustion of raw materials processed into solid fuel. By controlling the production process and production steps, the combustion process does not produce smoke and dust and does not pollute the atmosphere. "Recyclability" and "environmental protection".

We have established our wood pellet plants in several countries and regions of the world. Click setup wood pellets production projects by ABC Machinery to find out more information. Guide on process of wood production and how to start wood pellets business with limited cost in The Czech Republic, Guatemala, South Korea, Japan, Thailand, Indonesia, etc.

Booming Market: Start a Wood Pellet Manufacturing Plant Business

The wood pellet energy fuel is produced in the harmless and resourceful process of agriculture, forestry and urban and rural organic waste; all the living materials of biomass energy fuel can enter the biological cycle of the earth, and even the released carbon dioxide will be reabsorbed by plants and participate in the earth's cycle, so as to achieve zero emission. The material sustainability and recyclability of resources is a modern advanced production model. Therefore, the future of wood pellets is very optimistic.

ABC Machinery is dedicated to all kinds of biomass pellet production lines, whether you are a large-scale or small-scale wood pellet production line, allowing you to process high-quality wood pellets with low production costs and simple operating skills. It is the best choice to invest in the biomass pellet processing industry. We will provide you with investment plans at factory price, welcome to contact us!