Making wood or biomass pellets requires a pellet machine, also known as a pellet mill. If you are one of an increasing number of people, you may be researching on various ways on how to make wood pellets, or you are searching for information about the various kinds of pellet machines required to provide enough pellets.

In either of the case, you require to fully know the basics of pellet machines before you make any buying decisions. The following information is intended for helping you get an informed decision before you purchase a pellet machine. Keep in mind that an essential piece of equipment you will require to make pellets is the pellet mill machine, so be assured to familiarize yourself with their operation thoroughly.

When you first begin researching the pellet making process, you will find that there are only two various types of pellet mill machine that are used to make pellets. The contrast between these two choices comes down to the die that they use to make the pellets. These two types are known as the flat die type pellet mill and the ring die type pellet mill.

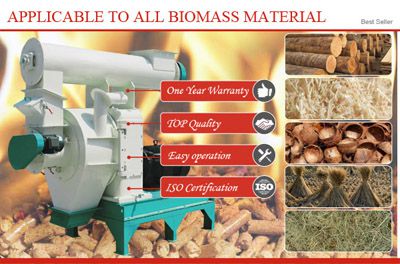

Ring die type pellet mill machine

The first is the ring die type pellet mill machine. As the name implies, it uses a ring die to make the pellets. What the ring die itself is a solid metal cylinder with openings pierced through the barrel around the perimeter. Inside the ring are the rollers that are used to force the material through the die. Raw elements in the form of wood waste or biomass are filled into the centre of the ring, and the rollers force them through the holes of the ring die. The finished pellets then emerge from the outside of the die.

The first is the ring die type pellet mill machine. As the name implies, it uses a ring die to make the pellets. What the ring die itself is a solid metal cylinder with openings pierced through the barrel around the perimeter. Inside the ring are the rollers that are used to force the material through the die. Raw elements in the form of wood waste or biomass are filled into the centre of the ring, and the rollers force them through the holes of the ring die. The finished pellets then emerge from the outside of the die.

This type of pellet mill machine is what you would see in most commercial pellet factory that produces a huge volume of pellets. The ring die type mill is a high cost, heavy-duty machine that is regularly out of the price range of most people that make their wood or biomass pellets.

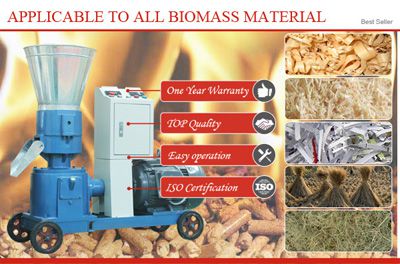

Flat die type pellet mill machine

The other one is the flat plate type pellet mill machine. This machine uses a flat plate to form the pellets. If you can imagine a meat blender, the die used in it is much related to that of the flat plate style pellet mill machine. The die is made from a deep round flat plate with many holes pierced through it. A set of rollers ride on the upper side of the plate, and when the raw feedstock is filled into the machine, the die rotates along with the rollers.

To make a better idea of how this system works, imagine a wheel on the end of the record player. This connected die and roller action forces the raw material through the die causing formed pellets to exit on the bottom of the die, where they fall into a slide and exit the machine. The flat plate type pellet mill is typically much less expensive than its ring die equal, and are mostly used by doing it yourself pellet generators.

They are also comparatively simple to work on and can be powered by some various methods. This, in turn, gives to the appeal of the flat plate mill to the small-scale generator. By utilizing a power source that you may previously own, you can save a lot of money by buying only the mill piece.