Recently, a complete 350kg/h wood chip briquette production line was shipped to Uruguay, and the customer purchased a small domestic briquette production line to make high-density biomass fuel from waste wood chips.

Wood Chip Briquetting Line Shipped to Uruguay

Photo Display:350kg/h wood chip briquette Production Line Built in Uruguay

If you are interested in our wood chip briquette processing equipment or have any questions, please feel free to contact our sales staff for consultation. Our machines are exported to the Czech Republic, Guatemala, South Korea, Japan, Thailand, Indonesia, etc. and other countries at the most favorable price. Please click the button below to get a free quote.

Brief Introduction of Wood Chip Briquette Equipment Technology

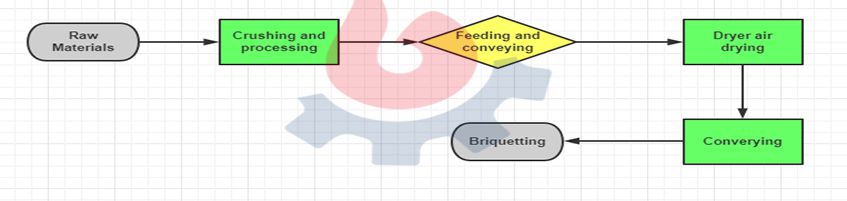

Wood Chip Briquette Production Processing

-

Crushing

The wood crushing plant is made up of three parts: the body, the intermediate body and the scattering clone. The intermediate body is equipped with bearings, crushing discs and screens. The main use of centrifugal action for crushing is driven by the motor through the bearings, which rotates the cutter disc and cutter head at high speed, causing the wood crusher to produce high speed airflow, which generates high intensity impact, compression and cutting force on the material to be crushed, thus achieving the effect of crushing. The crushing method used is the stamping method, using the relative movement inside the six movable pendants running at high speed and around the fixed tooth ring, so that the material is impacted by the whacking teeth, creating friction and impact between them, and the crushed material is sieved through the sieve holes into the receiving bag under the action of the rotating centrifugal force.

-

Drying

When using biomass as a feedstock to produce wood chip pellets and briquettes, the biomass must be dry enough so that it can be compacted into the form of pellets or briquettes. Biomass feedstock in the form of wood chips or agricultural waste is usually still wet and therefore needs to undergo a drying process first. Based on these conditions, drying with certain equipment needs to be completed. Dryers are characterised in industry by the ability to dry large volumes in a short time and economically.

The rotary dryer or drum dryer is one of the most widely used dryers in the pellet and briquette industry. This is due to the simple construction of the rotary dryer and its ease of operation and maintenance. Rotary dryers are used not only for drying biomass, but also in other areas such as minerals, fertilisers and some aggregates. The use of rotary dryers in many areas with various types of material also has an impact on many of the support equipment, such as the use of cyclones, scrubbers, baghouses and induced draft fans. Also from an operational aspect, indirect or direct drying is used, depending on the characteristics of the dried material, e.g. counter-flow or parallel drying.

-

Briquetting

The briquetting machine is the main equipment for making solid fuel in the form of rods using wood, rice husk, peanut shells, plant straw and other woody materials containing carbon (without adding any additives), under high pressure and high temperature conditions. It is capable of extruding granular (length ≤ 5mm, diameter ≤ 3mm) waste materials such as bamboo, wood, fruit shells, straw (except rice straw and wheat straw) with a water content of <12% into solid fuel rods with a central hole through a high temperature and pressure process without adding any binder.

| Briquette Specification Diameter | 8mm, 10mm, 22mm, 30mm, 70mm |

|---|---|

| Capacity | 0.8-1.2 t/hr |

| Briquette Density | 1000-1300 kg/m3 |

| Power of main engine | 45KW |

| Weight | 7000kg |