With global warming being one of the greatest threats to mankind because of uncontrolled use of fossil fuels, use of biomass as a fuel is the first step towards decreasing the dependency on non-renewable energy sources. It is a growing concern among the developed countries to reverse the damage by encouraging the use of other alternative sources. Using biomass pellets as energy fuel is one of the adopted practices in many parts of the world as a part of sustainable living. Before using the biomass as a fuel, it needs to be converted into pellets by a biomass pelletizer. All biomass including food wastes, agricultural wastes, wood scraps etc are condensed to form a uniform fuel resource. The biomass mixture is first treated with water at various temperatures to condition it for pelletizing. The biomass pelletizer machine used the principle of die and roller. The machine has dies with holes drilled inside them. When the mixture is fed into the machine after initial processing, the rollers press against the die and produce long strings of compressed biomass which is then cut into pellets. This process involves high pressures and temperatures to properly form the dense pellets. Once the pellets are dry, they become solid and sturdy to be used as a fuel.

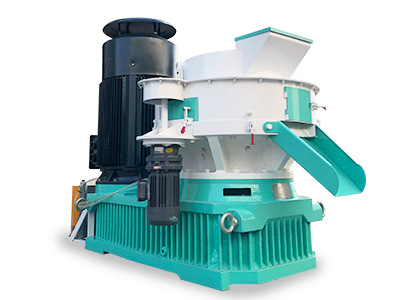

There are many types of biomass pelletizers available in the market depending upon the capacity and requirement of the consumer. Small pellet mills are used for small scale operations. The efficiency of these machines is less and the output rate is also low. Large scale production of biomass pellets requires industrial machines which have better efficiency and production rate. The raw materials required for biomass pelletizer is just good quality biomass such as saw dust, wood scrap etc. It is important to mention that the quality of pellets is directly dependent upon the quality of raw materials. Different raw materials make different quality pellets depending upon the cell structure of the wood.

The price of biomass pelletizer machines vary depending upon the type of product required. The capacity of these machines range from 50 kg/hour to 450 kg/hour. It is important to know the demands of the end consumers before investing in a pelletizer as using a large pelletizer for obtaining 50 kg of fuel is not a profitable venture. The electricity or diesel used to run the machine should be taken into account before making a choice as operating costs can be a major factor in calculating the profitability of the business.

In a world where non-renewable energy sources are being used callously without a thought, it is important to concentrate on alternative energy resources which can be utilized as fuels. Non-judicious use of fossil fuels is leading the world to a point of no return and complete dependency on alternative energy sources will be the future. Using biomass will not only lessen the burden on other sources but will also encourage recycling of waste materials. Invest in a biomass pelletizer to contribute to the energy resources and make a profitable business in the process.