Charcoal briquettes not only provide long-lasting heat compared to traditional non-renewable fossil fuels, but they also burn without smoke or odor. In addition, comparing to old-fashioned charcoal, investing in a charcoal briquetting factory is a low-investment, high-return project !

Investing a Charcoal Briquettes Processing Line with a Reasonable Price

With so many advantages, it is no wonder that the charcoal briquette is chosen by many countries’ customers, including India, Uganda, Kenya, and others, and widely used in domestic and industrial fields in recent years. So, what are the raw materials used to make the charcoal briquette? How is the charcoal briquette produced? What is the use of the charcoal briquette produced? This article will answer these questions one by one in detail.

Guide to Establish a Charcoal Briquette Making Plant for Business Starter

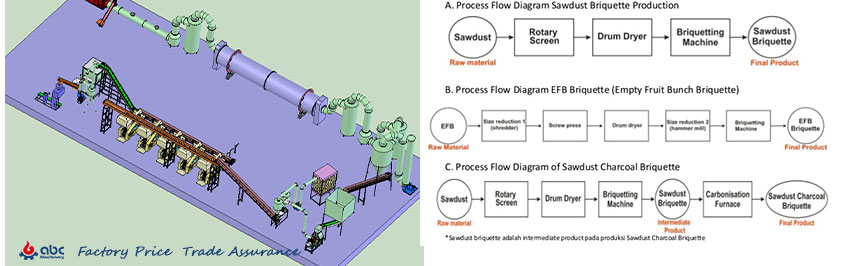

Charcoal Briquette Production Processing Flow Chart

How to produce high quality charcoal briquettes is one of the main concerns of many investors who are new to the charcoal briquette processing industry. Starting a charcoal briquetting plant is not an easy task. Before you begin, you have to understand the best charcoal briquettes production steps and then do a series of preparations (such as developing a business plan, choosing a site, investing capital, and purchasing supporting processing equipment. ) Generally speaking, the whole production process can be divided into five sections.

Step 1. Raw material collection

What are the main raw materials for manufacturing charcoal briquettes? Charcoal briquette is a dark or brown solid porous fuel made from sawdust, crop straw, peanut shells or other biomass waste through a series of working processes. Depending on the raw material, charcoal can be divided into three types: hardwood charcoal, softwood charcoal and mechanical charcoal. Hardwood charcoal can be produced from beech and oak; softwood charcoal can be produced from elm, basswood and willow; and mechanical charcoal can be produced from sawdust and other materials.

Step 2. Crushing Process

After a certain amount of raw material is prepared, it is crushed in a crusher or a hammer mill, usually into 5mm or smaller pieces to produce high-quality charcoal briquettes. However, if the raw material is already in powder forms, such as sawdust or bamboo powder, then this step should be omitted.

Step 3. Drying Process

The crushed raw material will be sent to the dryer to reduce the moisture in the raw material.

If the raw material is fed directly into the briquetting machine without drying, the volume of raw material with high moisture content will suddenly expand at a sharp increase in temperature, which may lead to an explosion. And the excessive moisture will increase the energy loss in the briquetting process, not only that, but it will also make the charcoal produced prone to bending and breaking after carbonization, which directly has a bad effect on the quality of the finished product. After drying, the water content of the raw material is reduced to about 10% for a uniform burning point.

Step 4. Briquetting Process

Briquetting is the core step of the whole making process. Upon entering the charcoal-making briquette machine, the raw material will be subjected to three types of forces: the frictional force, the centripetal force from the walls, and the main driving force from the briquetting machine. Under these three forces, the prepared raw material will be pressed into a bar shape. As the charcoal briquettes are discharged from the bottom of the machine, they can retain their shape due to the moisture, the binder, the temperature (about 105℉ or 40℃), and the pressure of the briquette machine. It should be noted that the charcoal briquettes obtained in this step are not completely carbonized, but only the surface is highly carbonized, so they are semi-finished charcoal biomass briquettes.

Step 5. Carbonation Processing

Carbonization is an important part of the charcoal briquette-making process. The carbonization process is the core of the technology for making charcoal briquettes. With the development of society and the awakening of environmental awareness, the charring step is usually carried out in a charcoal furnace. The charcoal kiln used before is time-consuming and polluting to the environment, so more users choose to use charcoal carbonization furnaces in recent years.

Buy Hot Sale Charcoal Briquette Making Equipment from ABC Machinery

Choosing a reliable and cost-effective charcoal briquetting equipment manufacturer and supplier is important to establish a charcoal briquette production plant.

ABC Machinery is a professional biomass pellets and briquettes manufacturing company that has its own plant and R&D team to provide factory-priced equipment and professional services. (Related articles: charcoal briquette manufacturing process flow chart>>)

Charcoal Briquetting Production Equipment

The screw briquette processing machine offered by ABC Machinery has many favorable features. It is compact in design, energy efficient, easy to maintain and operate. Most importantly, it can also be used to process a wide range of agricultural and domestic wastes such as: rice husk, sawdust, bamboo, coconut husk, paper, straw, wood, etc. After high pressure and high temperature pressing, the shape can be changed according to the shape of the forming cylinder, round, square or polygon.

The Application of The Charcoal Briquetting Products

-

The application spectrum for charcoal briquettes is wide. Charcoal briquettes are more than three times denser than charcoal, and they do not produce a lot of smoke when burned, so they can take carbon’s place for barbecue.

-

In industry, charcoal briquettes are used in the production of carbon disulfide and in steel smelting.

-

Charcoal briquettes are also used as supplementary fuel for boilers because their density is close to that of coal, with a calorific value of 5,500-7,000 calories per kilogram, but their ash content is obviously lower than that of coal.

Video of Charcoal Briquette Production Line

Winter is almost upon us again in the Northern Hemisphere, and it will get even colder due to the weather anomalies. Burning is a traditional way of heating and non-renewable fossil fuels such as coal, oil and natural gas now seem unable to meet the needs of today's growing population and sustainable society. As a result, the import and export of charcoal briquette industry has become a profitable business (especially in the European and North American markets). For manufacturing costs of charcoal briquette making machine, please contact us for a free quote!