The global rabbit industry is expanding rapidly, driven by the growing demand for meat rabbits, pet rabbits, and rabbit hair production. Rabbit meat is highly valued as a lean, protein-rich option for health-conscious consumers, while the number of households raising rabbits as pets continues to rise. This trend is creating a stronger demand for safe, nutritious, and convenient rabbit pellets. Meanwhile, the angora wool market also shows steady growth, highlighting the importance of professional rabbit feed formulation to improve hair quality and maintain long-term productivity.

Profitable Rabbit Pellet Making Business

As this demand intensifies, farmers and feed producers are moving away from traditional powder feeding and increasingly focusing on making rabbit pellets with modern equipment. At the center of this transformation is the rabbit pellet making machine, which ensures efficient processing, consistent pellet quality, and tailored nutrition. Whether for small-scale farms or large commercial projects, a reliable rabbit feed pellet machine provides stable performance, higher efficiency, and customized solutions to meet the specific feeding requirements of different rabbit farming sectors. This article will detail how the rabbit pellet making machine can help boost your farming and business plans, guiding you toward smarter and more profitable rabbit feed production.(Related Posts:Making Rabbit Feed Pellets)

Problems with Traditional Feeding and the Value of Rabbit Pellets

Issues with Powder Feeding

Traditional rabbit feeding with powder feed often results in waste, unbalanced nutrition, and low efficiency. Loose powder scatters easily, increasing costs, while rabbits tend to pick out only their favorite ingredients, leading to poor growth. Manual feeding is also time-consuming and labor-intensive. By making rabbit pellets, farmers can solve these challenges—pellets ensure consistent nutrition, reduce feed waste, and save labor. A modern rabbit pellet making machine transforms raw materials into balanced pellets, directly improving farm productivity and profitability.

Rabbit Pellets with Tailored Feed Formulation

Rabbit Feed Formulation: The Foundation of Rabbit Pellets

At the core of producing high-quality rabbit pellets lies proper rabbit feed formulation, which ensures every pellet provides complete nutrition. Young rabbits need 20–24% protein, while adults require 16–18%; crude fiber should be maintained at 15–20% to support digestion; and the calcium-phosphorus ratio should be around 2:1, with added vitamins A, D3, and E. Fat content is best kept within 2–3% to avoid obesity or digestive problems. Common ingredients include hay, cornmeal, soybean meal, wheat bran, and carrot pulp. If the formulation is unbalanced, rabbits may suffer from digestive disorders, higher mortality, or reduced meat and fur yields. With the support of a reliable rabbit feed pellet machine, farmers can accurately mix and process these ingredients, ensuring uniform and nutritious rabbit pellets that strengthen rabbit health and maximize production efficiency.

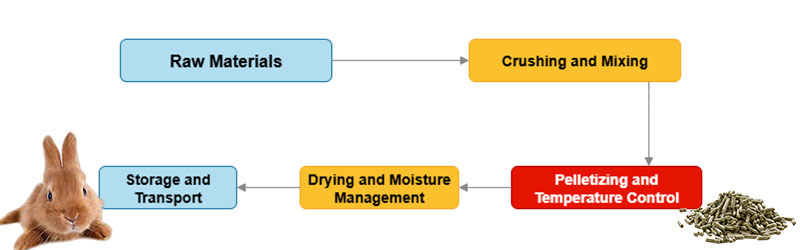

Making Rabbit Pellets: From Raw Materials to Storage

Crushing and Mixing

Raw ingredients must be finely ground and mixed before pelletizing. A rabbit feed pellet machine guarantees even mixing for balanced feed.

Pelletizing and Temperature Control

The rabbit pellet making machine presses ingredients into pellets at controlled temperatures. This prevents vitamin loss and ensures pellet durability. Pellet size can be adjusted: 3–4 mm for young rabbits, 6–8 mm for adults.

Drying and Moisture Management

To produce durable rabbit pellets, moisture content should be kept at 10–12%. With advanced drying systems, the rabbit pellet making machine ensures pellets do not mold or break apart.

Step-by-Step Process of Making Rabbit Pellets

Storage and Transport

Pellets should be stored in sealed bags or silos, in dry and ventilated spaces. Proper packaging extends shelf life to 3–6 months. Moldy pellets are harmful, so a reliable rabbit pellet making machine combined with safe storage practices guarantees feed safety.

Want to ensure every step from raw material to storage is efficient? ABC Machinery’s rabbit pellet making machines deliver balanced nutrition, durable pellets, and safe storage solutions for long-term success.

How to Maximize Efficiency and Profit with a Rabbit Pellet Making Machine

Enhance Processing Efficiency and Feed Quality

Investing in a modern rabbit pellet making machine can significantly improve your rabbit feed production. These machines are fully automated, processing between 200 kg and 2 tons of raw materials per hour, which greatly reduces production time. Their optimized energy-efficient design saves 20%-30% of energy compared to traditional feed equipment, lowering overall operational costs.

The pellets produced are uniform and compact, promoting better digestion and nutrient absorption while reducing food waste. Additionally, the rabbit feed pellet machine allows the incorporation of vitamins, minerals, and other nutrients, ensuring that rabbits receive balanced nutrition to support growth, health, and reproductive performance.

Choosing the Right Rabbit Pellet Making Machine for Your Farm

Selecting the right machine depends on your farm size, feed production needs, and desired versatility:

- Small Farms: Compact rabbit feed production machines with 200–300 kg per hour capacity are ideal. They are affordable, easy to operate, and suitable for daily feeding routines.

- Commercial Farms: Large-scale farms benefit from high-capacity, automatic rabbit pellet making machines with adjustable production rates and automated feeding systems, perfect for industrial-scale rabbit feed production.

When evaluating equipment, consider durability and adaptability. High-quality rabbit pellet makers can process a variety of raw materials such as hay, soybean meal, and grains. Core components, like molds and rollers, are made from wear-resistant alloys for long service life and minimal maintenance. Typically, the ROI for a rabbit feed pellet mill is 6–12 months, with maintenance costs accounting for only 5% of total operating expenses.

Investing in a reliable rabbit pellet making machine ensures consistent feed quality, reduces production costs, and maximizes profitability, making it a smart choice for any rabbit farm.

Boost efficiency and cut costs with ABC Machinery’s rabbit pellet making machines—from small farms to large commercial plants, we provide tailored solutions to fit your needs.

Why Choose ABC Machinery’s Rabbit Pellet Making Machine?

When investing in feed equipment, ABC Machinery stands out with its superior rabbit pellet making machines, designed to meet the needs of both small-scale farms and large commercial feed plants. Reliable, efficient, and easy to operate, our machines help farmers produce high-quality rabbit pellets while reducing labor and operational costs.

Key Benefits of ABC Machinery’s Rabbit Pellet Making Machine

- Multi-purpose pelletizing: Suitable for a variety of raw materials including hay, corn, soybean meal, wheat bran, and more.

- Customizable pellet size: Adjustable pellet diameter to suit different rabbit growth stages.

- High efficiency and low energy consumption: Save production costs while maximizing output.

- Easy operation and maintenance: User-friendly design makes it ideal for small farms or family operations.

- Safe and eco-friendly: Low noise and dust-free operation ensures a healthy environment for both rabbits and operators.

Advanced Technology and Durable Design of ABC Rabbit Pellet Machines

- Direct manufacturer supply: Lower cost with strict quality control and guaranteed reliability.

- High-precision transmission: Advanced gear drive and compensating coupler for stable, low-noise performance.

- Durable construction: Thickened main shaft (+15%) and high-strength bearings reduce failure rates by 30%.

- Premium components: Equipped with German FAG bearings and direct lubrication channels for consistent operation.

- 24/7 continuous operation: Automatic lubrication system supports round-the-clock production.

- Wide model range: From small-scale rabbit feed pellet machines to large industrial production lines, covering all farming and business needs.