Nowadays pig feed pellet market demand shows growth. With the improvement of people's living standard, the demand for pork and pork products is increasing, and the pig industry is also developing rapidly. This has led to an increase in the demand for pig feed pellets, as pellets have the advantages of balanced nutrition, easy storage and use. In addition, the breeding model is gradually becoming large-scale and standardized, and pellet feed is favored by investors in livestock pellet feed factories for its precise proportions and convenient management.(Read More: Construction of Industrial Pig Feed Processing Plant for Profits)

Pig Feed Making Pellets Manufacturer & Suppplier

As a result, an increasing number of animal feed pellet investors and businessmen are making enquiries to ABC Machinery to learn more about chicken, cattle, sheep, pig food processing technology and how to start an animal feed production business. For more details, please feel free to contact us!

How to Make Feed Pellets for Pigs in 5 Easy Steps

Various Raw Materials for Livestock Feed Pellet

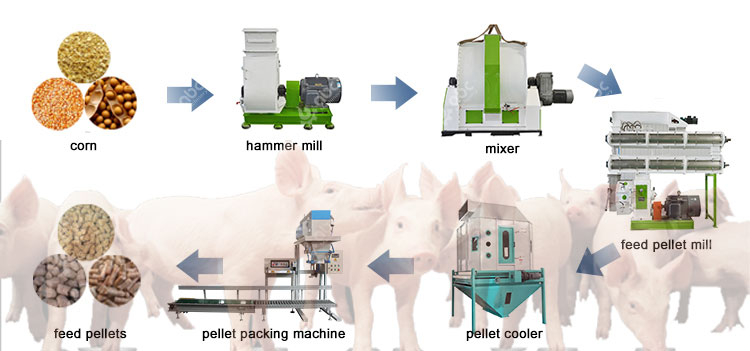

The production of pig feed pellets is a complex process that involves multiple components and requires careful design and execution. Each step is critical, from the selection and processing of raw materials to the pellet forming and packaging. Here are the five steps typically involved in making pig feed pellets:

-

Step1 Pig Feed Pellet Raw Material Preparation & Pre-processing:

Preparing various raw materials such as grains, soybean meal, fish meal, etc. according to the formula, and conducting preliminary cleaning, screening and crushing can improve production efficiency and ensure the quality of raw materials.

-

Step2 Pig Feed Mixing Ingredients:

Put various raw materials into the mixer according to a certain formula ratio and mix them to ensure the balance of various nutrients in the granules.(send enquiry to learn more)

| Various Types of Pigs | Feed Mixing Ratio (%) | |||||

|---|---|---|---|---|---|---|

| / | Corn | sorghum | rice bran | wheat bran | soya bean cake | fish meal |

| 5~15kg piglets | 27.5 | 5 | - | 2.5 | 10 | 3 |

| 15~30kg medium pig feed | 35 | 20 | - | 20 | 23 | - |

| 30~60kg growing pig | 30 | - | 10 | - | 8.5 | 1.5 |

| Feed for large pigs from 30kg to farrowing | 27.5 | - | 15 | - | 7.5 | - |

-

Step3 Pig Feed Tempering and Pelleting:

According to the different growth stages and needs of the pigs, add appropriate amounts of vitamins, minerals and other nutrients for steam ripening. The mixed materials are processed by a feed pellet machine and pressed into pellets by extrusion and cutting. In this step, it is necessary to select the appropriate pellet machine and mold according to different needs.

Ring Die Pig Feed Pellet Making Machine For Sale

-

Step4 Cooling Process:

Place the newly produced hot pig feed pellets into a cooling machine for cooling to prevent the pellets from absorbing moisture and deforming, and to reduce oxidation and deterioration during subsequent storage.

-

Step5 Screening and packaging:

The cooled pellet feed is screened through a screening machine to remove unqualified pellets, and then the qualified pellets are packaged for storage and transportation.

Note: For growing pigs, the size of feed pellets is usually determined according to their weight and growth stage. Taking growing pigs as an example, growing pigs weighing between 20-50kg are suitable to consume pellet feed with a diameter of 3-4mm; while growing pigs weighing between 50-100kg are suitable to consume pellet feed with a diameter of 4-6mm. Of course, this is only the general situation, the specific feed pellet size should also be determined according to different regions, different breeds of pigs and the growing environment and other factors.

Buy Reliable Pig Feed Pellet Line for Business

Pig Feed Pellet Making Process

From the above flow chart, it can be seen that the pig feed pellet production line mainly includes hammer mill, feed mixer, screw conveyor, storage silo, feed pellet machine, feed pellet cooler, feed pellet packaging machine and other components. When the pig feed pellet raw materials are collected to the animal feed processing plant, they will go through a series of professional processes, and finally get the high quality animal feed pellets with balanced nutrition. However, choosing the most suitable pig feed pellet manufacturing equipment is not an easy task. All feed production manufacturing equipment must match the processing capacity and capital investment of the feed pellet plant.

Successful Establishment of Feed Pellet Manufacturing Business for Pig/Swine/Hog

Headquartered in Anyang, China, ABC Machinery has accumulated extensive experience in animal feed pellet processing and feed feeding. We are able to design and build feed pellet processing plants independently. What's more, our palm oil processing equipment prices are absolutely competitive in today's market. We can promise that we are the best partner to help you start your pig feed pellet business and the best pig feed manufacturing equipment supplier.

If you want to start a successful pig feed manufacturing business, or if you want more details about how to start an animal business. Please do not hesitate to contact us. We are always at your side. Feel free to ask any questions!