The increasing attention to animal health and the growing awareness of balanced feed nutrition and the benefits of additives in feed have led to a huge growth in the animal feed market. According to the reports, the animal feed market reached at US$ 21.61 billion in 2018 and is expected to reach US$ 26.62 Billion by 2023. In terms of animal production, the poultry industry is the largest and the fastest growing sector. Correspondingly, poultry feed occupies the largest share of the global feed processing market. Poultry feed pellet manufacturers are investing heavily in the development of innovative feed pellet machine and feed processing technology for the production of high-quality animal feed pellet.

Poultry Feed Pellet Markets

Key Factors to Setup Poultry Feed Pellet Mill Plant

There are many factors should take into consideration when you are planning to set up a poultry feed mill plant, among which the most important are investment capitals, feed pellet mill machine, factory site, feed production capacity, feed ingredients and formula, and more other factors. So, how much a poultry feed pellet mill project will cost? What equipment is more suitable?

Actually, all these factors are closely related. The cost of a poultry feed mill plant largely depends on poultry feed pellet making machine price and specific feed production capacity. That is to say, the core of poultry feed mill plant is the animal feed processing machine. ABC Machinery offers customized plan for animal feed processing plant, including equipment and feed manufacturing process selection, factory layout design, project installation, and more. If there are any questions, please contact us for more detailed information!

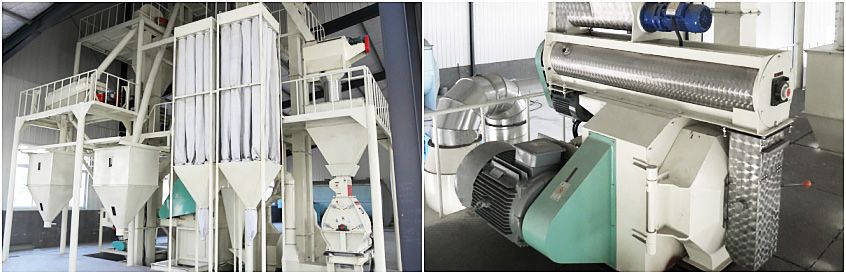

Small Poultry Feed Mill Plant Equipment Inspection

How to Choose Poultry Feed Pellet Mill?

When our salespersons and project engineers chatted with animal farmers, they found that many people had no ideas about animal feed pellet mill before, so they were often unable to choose the most suitable one. Many of them are blindly pursuing cheap prices, but they do not really understand why should buy such a feed pellet making machine. So, in most cases, either the machine can not be used, or the capacity of the machine can not reach their expected output. Therefore, today we will analyze the most popular two main feed pellet machines in the market, Flat Die Pellet Mill and Ring Die Pellet Mill, hoping to help you to choose the most suitable animal feed pellet machine to build an efficient poultry feed mill plant.

- Case 1: The Proportion of Grass Powder in Feed Ingredients is Large, and the Output is Small

It is generally recommended to use a flat die pellet machine. If the output is large, you can use the ring die pellet machine that is strengthened with feeder. Because the content of grass powder is too much, the overall material weight will be lighter, and the feeding angle of the ring die pellet machine is smaller, which will affect the feed speed. It should coupled with a forced feeder to push the feed, the effect will be much better. In addition, the ring die pellet machine contains a scraper device, which effectively prevents the machine from being blocked due to excessive material. The flat die pellet machine is more suitable for granulation with small output, which is more convenient to operate and the feed inlet is relatively larger. (Read more: Chicken Feed Making Machine >>)

Small Poultry Feed Mill Plant

- Case 2: The Grass Meal Takes Less in Feed Ingredients or To Make Concentrated Feed

When making concentrated feed, or grass meal takes up less in the feed ingredients, such as pig feed, chicken feed or full-price feed, ring die feed pellet machines are generally used. But, if the output is small, flat die pellet machines can be used. Because the sealing performance of the ring die pellet mill machine is better than that of the flat die pellet mill, a large amount of dust will not be generated during the granulation process. Moreover, the degree of ripening of the ring die pellet machine will be higher than that of the flat die pellet machine, and the gloss will be better. (Read more: Making Grass Pellets for Feed >>)

Commercial Poultry Feed Manufacturing Plant

In fact, the main reason for choosing the ring die pellet machine or the flat die pellet machine is based on the output. If it is a family farming and the output requires self-sufficiency, then the flat die pellet machine can be satisfied, and the flat die pellet machine is cheaper than the ring die pellet machine. If it is a feed processing plant or a large or medium-sized farm, it is still recommended to use a ring die feed pellet machine, which has high output and low pollution. The feed can be used by itself or packaged for sale.

If you are still having questions about setting up poultry feed mill plant or the purchase of poultry feed pellet machine, please tell us cearly and our professional service staff will get back to you as soon as possible!

World Main Poultry Production Countries

| No. | Country | Production (Milion) |

|---|---|---|

| 1 | China | 5774.48 |

| 2 | Indonesia | 2384.15 |

| 3 | United States of America | 1973.38 |

| 4 | Brazil | 1468.35 |

| 5 | Iran | 1071.61 |

| 6 | India | 801.09 |

| 7 | Mexico | 568.37 |

| 8 | Pakistan | 524.14 |

| 9 | Russia | 507.05 |

| 10 | Turkey | 353.56 |